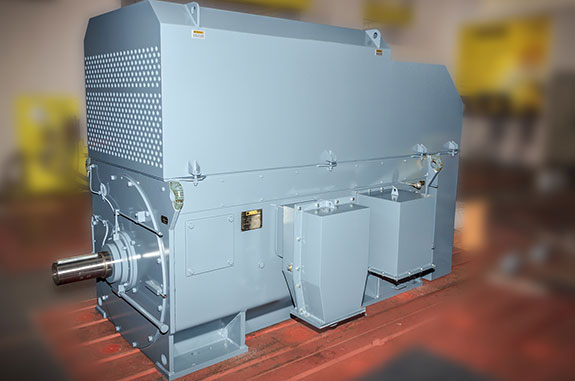

Motor with unusual shaft diameter shipped to Cairo from Berlin

Published by Joseph Green,

Editor

World Cement,

Menzel Elektromotoren GmbH has delivered a mechanically and electrically identical replacement for a failed slip ring motor that had served as a crusher drive in Cairo.

Menzel constructed the new motor in a design and form factor that is completely compatible to the old Siemens motor. Notably, this included a shaft with a diameter of only 127 mm, which is exceptionally slim for the required motor size and overall motor weight of 6000 kg. In addition, the client asked for the exact same type of terminal boxes to be installed in exactly the same positions.

The 6-pole motor is a 932 kW unit with a rated voltage of 6300 V and a speed of 989 min-1. Menzel also equipped the new drive with the same type of dual-sensor vibration monitoring as the old motor. The replacement motor, designed to be easily swapped out when necessary, was not only built by Menzel in Berlin. The manufacturer also took care of its installation and commissioning on location. The Egyptian customer, a long-standing Menzel partner due to several similar successfully completed projects, also received a number of spare parts, such as carbon brushes, slip ring bodies and brush-holders.

Adapted from press release by Joseph Green

Read the article online at: https://www.worldcement.com/product-news/02122015/menzel-mechanically-slip-ring-motor-96/

You might also like

The World Cement Podcast - CleanTech & Venture Capital

Our guest for this episode of the World Cement Podcast is Alfredo Carrato, Venture Capital Advisor for CEMEX Ventures. Listen in to the conversation as World Cement's Senior Editor, David Bizley, and Alfredo discuss the role of venture capital and cleantech in enabling the cement industry's green transition.

Tune in to the World Cement Podcast on your favourite podcast app today.