IFC to support WHR utilisation in the cement industry

Sustainable solutions

On 8 – 11 September 2014, Latin American cement producers and international suppliers gathered in Santo Domingo, Dominican Republic, for the XXXI Technical Congress FICEM. The event included a three-day conference programme, during which industry specialists presented papers on various issues facing the sector along with technical details of expansion, environmental and upgrade projects recently carried out in the region’s cement plants. Preceding the congress, the International Finance Corporation (IFC) – a member of the World Bank Group, signed a memorandum of understanding with the Inter-American Cement Federation (FICEM) that aims to provide support for sustainable cities in South, Central America and the Caribbean, and promote clean technologies within the region’s cement industry.

Representatives from IFC also delivered presentations at the event; Kristtian Rada talked through investing in sustainable cities in Latin America and the Caribbean, while Luis Alberto Salomon discussed the potential for waste heat recovery (WHR) projects within the cement sector.

Together with the Institute for Industrial Productivity (IIP), IFC recently published a report on ‘Waste Heat Recovery for the Cement Sector: Market and Supplier Analysis’. The report outlines uptake of WHR technology to date, geographical cement markets that have the potential to benefit from WHR systems, the advantages provided by the technology, as well as project economics and payback.

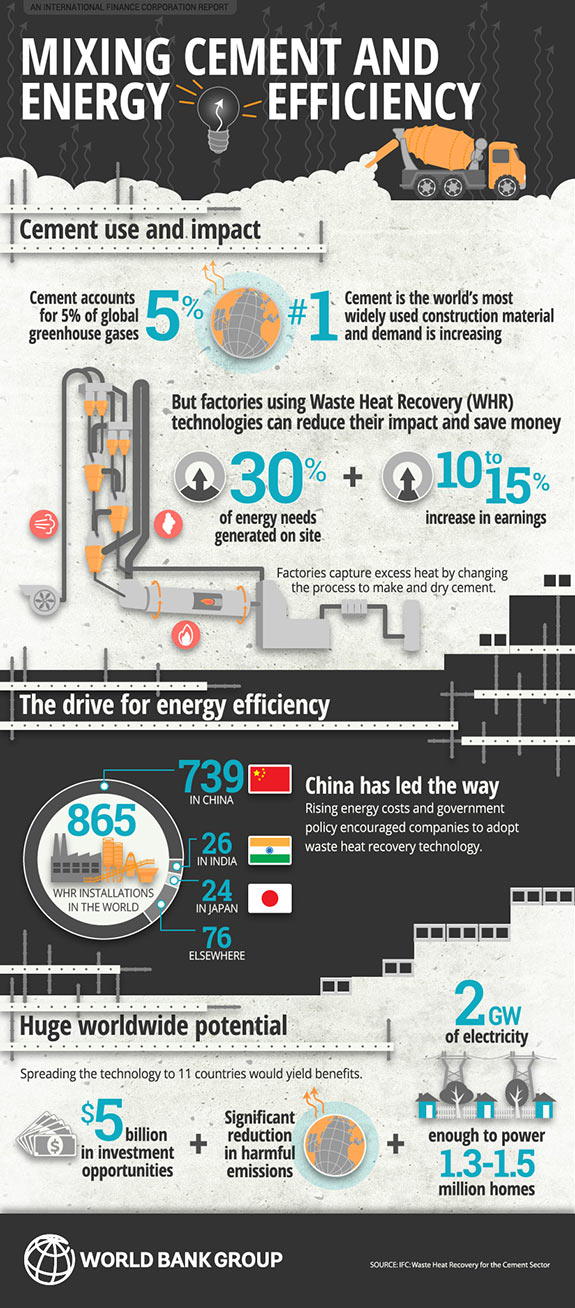

At present, WHR utilisation is heavily weighted in China, which currently boasts 739 installations. This compares to just 126 systems in the rest of the world. The report estimates that with an investment of around US$5 billion, WHR technology could generate some 2 GW of power. Considering that WHR installations can enable cement plants to generate up to 30% of their electricity requirements, this technology represents a significant opportunity for the industry and one that IFC is keen to support. As Michel Folliet, IFC Chief Industry Specialist, notes: “Cement companies can get more reliable and cheaper energy and at the same time cut their greenhouse gas emissions.”

Benefits of WHR

According to the report, WHR utilisation can reduce operating costs and improve a cement facility’s EBITDA margin by approximately 10 – 15%. Other advantages include reduced need for purchased power or reliance on fossil fuel-based captive power plants, as well as lower susceptibility to rising electricity prices and/or unreliable power supplies.

Mixing cement and energy efficiency (Image shared courtesy of IFC, part of the World Bank Group).

Potential markets and opportunities

The report identifies Asia and Latin America as strong potential markets for WHR installations, and notes that certain African and Middle Eastern countries also offer opportunities for its use. An in-depth analysis is provided on the following countries: Brazil, Mexico, Nigeria, South Africa, India, Pakistan, Egypt, Turkey, Philippines, Thailand and Vietnam.

IFC support

IFC is exploring opportunities to work with equipment manufacturers and vendors in order to promote WHR within the cement industry. It will also look at ways to lower the financial risk associated with installing the technology. IFC has already helped Cimko Cimento to mobilise US$25 million for a WHR project, providing the Turkish cement producer with a US$40 million loan.

“IFC focuses on helping the market realise the WHR opportunities by putting together innovative financial structures that will satisfy cement producers, WHR operators, and bankers, and then financing such projects,” explains Folliet.

You can download the ‘Waste Heat Recovery for the Cement Sector: Market and Supplier Analysis’ report here.

Written by Louise Fordham

Sources:

- IFC

- World Bank Group

- XXXI Technical Congress FICEM (some photos of the event can be found here)

Read the article online at: https://www.worldcement.com/the-americas/26092014/ifc-promotes-waste-heat-recovery-for-the-cement-industry-555/

You might also like

Rohrdorfer starts ethylene production from carbon dioxide

Following a test phase, production is to be scaled up to an industrial scale, thereby establishing a seamless CO2 circular economy.