NORD to showcase dynamic integrated drives at exhibition in Nuremberg

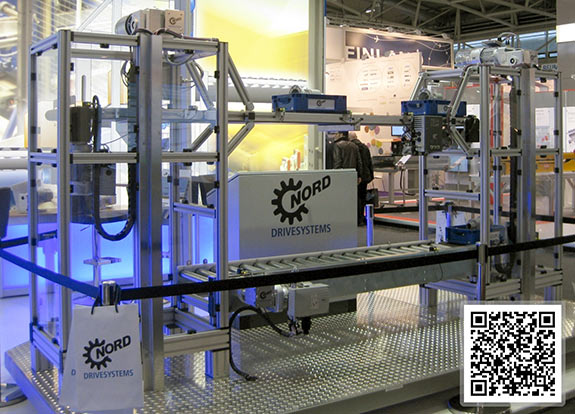

At the SPS IPC Drives exhibition in Nuremberg, Germany, NORD DRIVESYSTEMS (hall 3, stand 218) will demonstrate the coordinated operation of dynamic integrated drives in a working intra-logistics model.

Efficient geared motors combined with distributed frequency inverters and motor starters accomplish demanding positioning tasks. Functions that will be demonstrated include contact-free and gap-free baggage accumulation. The drives are synchronised and thereby enable the seamless transfer of transported goods to a hoist. Motor encoders and sensors are wired directly to the mechatronics units, which carry out different tasks and feature a uniform operation concept. The economic SK 135E motor starter ensures load pick-up with constant speeds as well as reversing operation. The SK 180E frequency inverter controls the speed of horizontal conveyors. The versatile SK 200E series performs drive tasks in hoist applications. These inverters cover motor performances up to 22 kW and can also be used for regenerative operation thanks to a brake chopper and a braking resistor.

An intra-logistics model at the NORD DRIVESYSTEMS exhibition stand will show the perfectly synchronised operation of different drives in conveyors and hoists. (The QR code links to a video demonstration).

The units’ proven field-oriented vector control enables high dynamics and steady operation even during heavy load fluctuations. A generous overload capacity of 150% for 60 s and 200% for short periods ensures increased reliability and a long service life. In the exhibition model, the controller and the drives communicate via Profibus. In addition, NORD provides other industry standard communication options such as Profinet or EtherNet/IP. Further exhibits include highly efficient motors according to all efficiency classes and series SK 500E cabinet inverters for motor performances up to 160 kW.

Adapted from press release by Louise Fordham

Read the article online at: https://www.worldcement.com/product-news/20112014/nord-drivesytems-to-showcase-technology-at-sps-ipc-125/

You might also like

Rohrdorfer starts ethylene production from carbon dioxide

Following a test phase, production is to be scaled up to an industrial scale, thereby establishing a seamless CO2 circular economy.